Why use increase viscosity film when polishing optical fiber?

Why use increase viscosity film when polishing optical fiber?

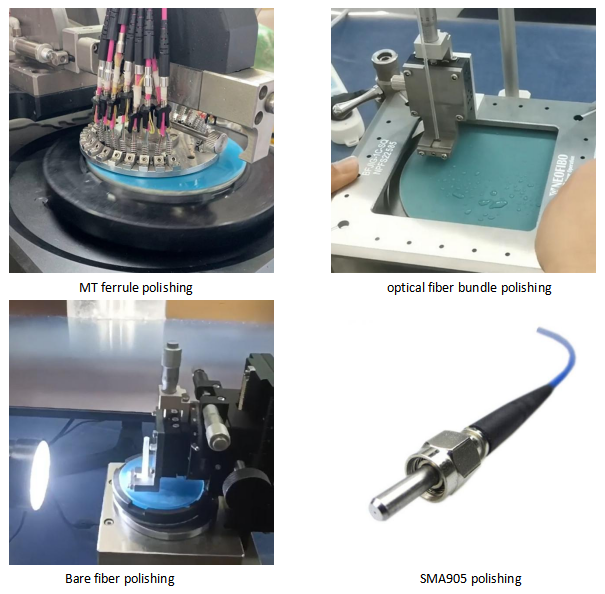

The increase viscosity film, also known as (tackifying film, or sandpaper adsorption film), is often used for MPO ferrule polishing, SMA905 polishing, optical fiber bundle polishing, plastic optical fiber polishing, fiber array and small-profit crystal polishing, etc. Stick it between sandpaper and polishing pad (rubber pad or glass pad) to prevent the sandpaper from falling off during polishing; Increase viscosity film pad used to increase the viscosity or adsorption capacity of optical fiber polishing rubber pad and glass pad.

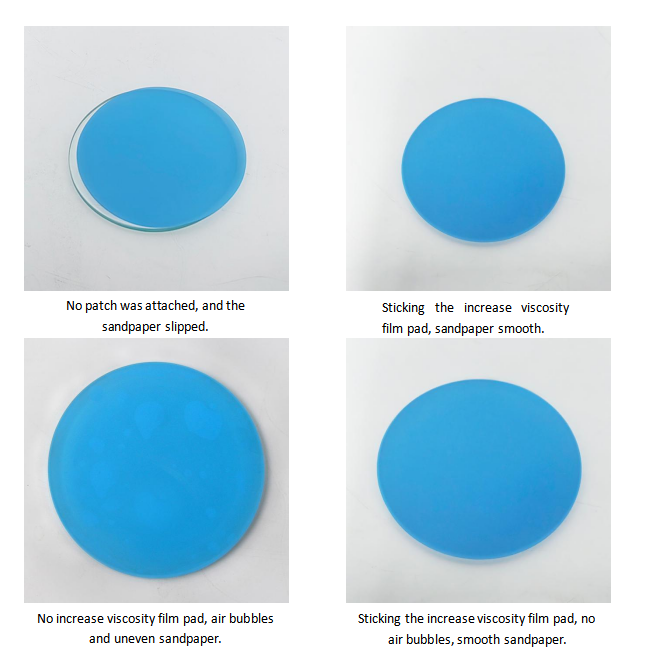

1.The benefits of using increase viscosity film .

(1) Prevent the sandpaper on the glass pad from slipping;

(2) Eliminate bubbles when sandpaper is attached;

(3) Enhance the adsorption capacity of glass pad, rubber pad, and steel pad polishing;

(4) Prolong the service life of the rubber pad;

(5) Stick sandpaper evenly and grind it evenly to prolong the service life of sandpaper.

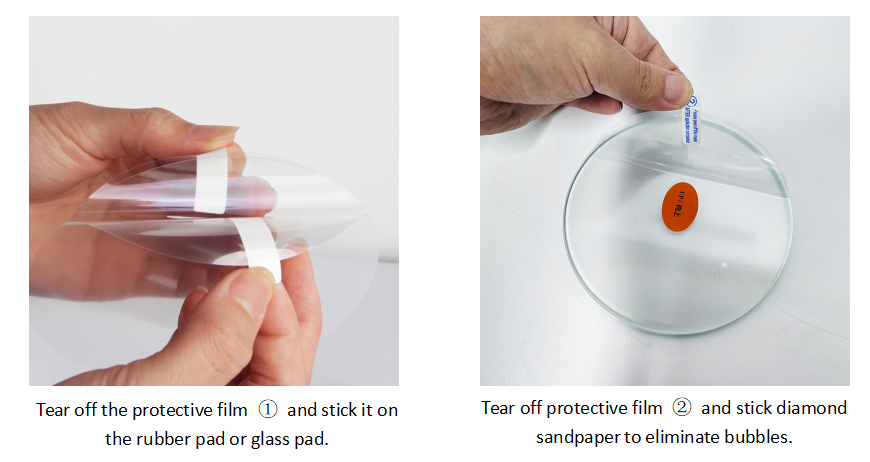

2.How to stick the increase viscosity film ?

3.The application scenario of increase viscosity film .

The increase viscosity film is commonly used in MT ferrule polishing, SMA905 polishing, optical fiber bundle polishing, plastic optical fiber polishing, optical fiber precision assembly polishing and so on.