Categories of Polarization Maintaining Fibers

Categories of Polarization Maintaining Fibers

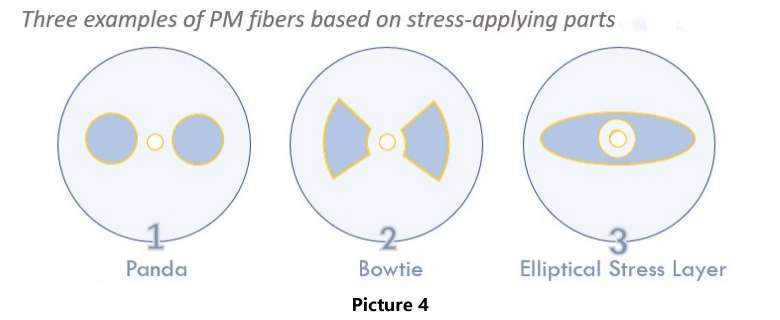

There are many types of polarization maintaining fibers, which can be divided into high birefringence optical fibers (birefringence coefficient B~10-4) and low birefringence optical fibers (B~10-7; B~10-9) according to the size of birefringence.

According to the generation mechanism of the birefringence phenomenon, it can be divided into structural birefringence and stress birefringence, with the former introducing birefringence through the asymmetry of the structure of the light-conducting material, and the latter introducing birefringence through the change of the refractive index of the material caused by stress (i.e., photo-elastic effect). After decades of development, there exist a variety of technical solutions for both high birefringence and low birefringence, and 【Picture 1】basically summarizes the classification of polarization maintaining fibers.

Low birefringence optical fibers are mainly used for polarization initiation and preservation of circularly polarized light, and can be developed by rotating prefabricated rod technology (which is also suitable for manufacturing rotating high birefringence optical fibers). High birefringence optical fiber, can be divided into two types, single polarization and double polarization: general polarization preserving optical fiber supports two orthogonal polarization modes LP01x and LP01y, called double polarization; single polarization optical fiber is specially designed and fabricated so that one of the two orthogonal modes cuts off or produces serious leakage and attenuation, and only a single mode is able to propagate in it. Single-polarized fibers are mainly used in scenarios that require high extinction ratios or polarization mode dispersion.

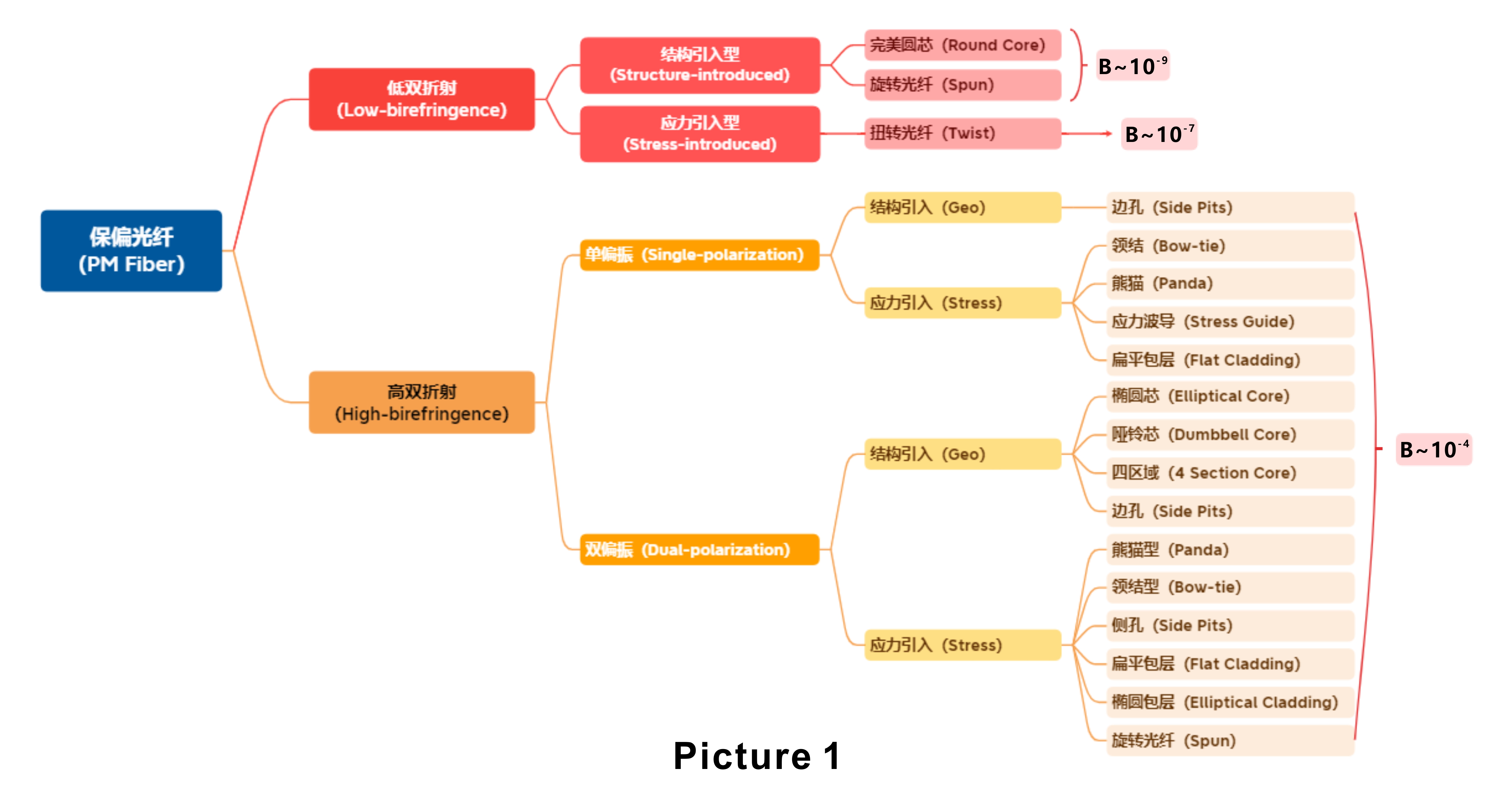

【Picture 2】shows the rotating bowtie-type bias-preserving optical fiber produced by THORLABS, whose bowtie-type stress zone rotates along the fiber axis, which can be made into a low birefringence optical fiber or a high birefringence optical fiber.

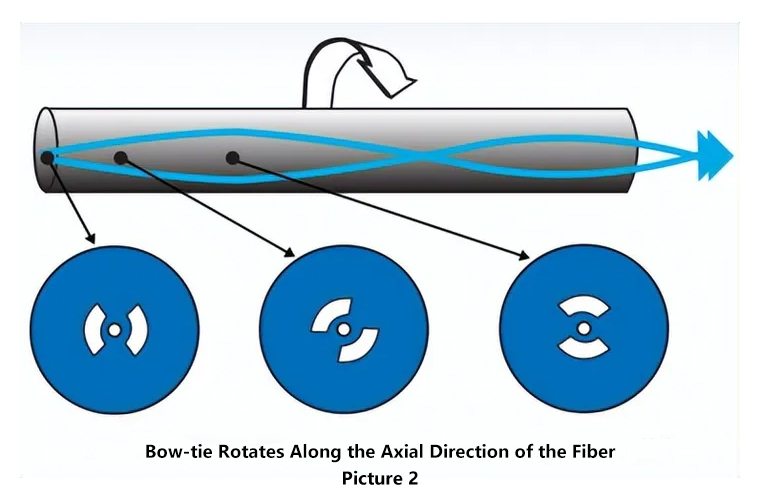

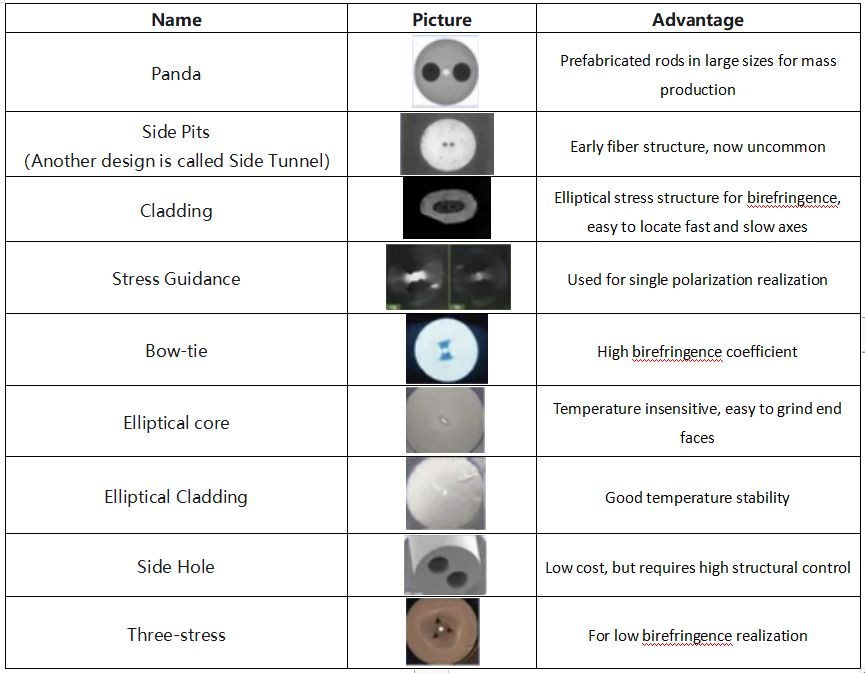

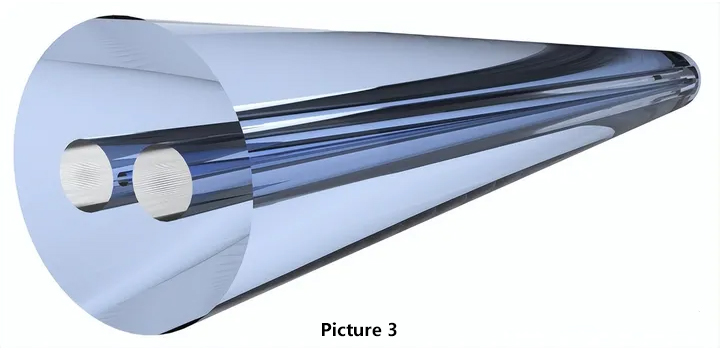

In practical applications, in addition to the requirements for the performance of the optical fiber itself, it is also necessary to examine whether the optical fiber is easy to manufacture and use. As shown in 【List 1】, after the appearance of bias-preserving optical fibers, there exist a variety of structures and types, but after these decades of development and screening, the most common types of bias-preserving optical fibers in the current international are the panda, bow-tie (as shown in 【Picture 2】), elliptical cladding and elliptical core structure of the optical fiber. Among them, due to the suitability for mass production, most of the bias-preserving optical fibers in China adopt the Panda (PANDA) type of bias-preserving optical fibers, whose structural three-dimensional diagram is shown in 【Picture 3】.

List 1:Various structures and their characteristics that emerged during the development of PM fibers

【Picture 3】Cross-sectional view of panda-type PM fiber and three-dimensional view of the overall structure (polymer coating material is not identified)

Elliptical cladding type, bow-tie type and panda type are three types of widely used three types of PM fibers, all of which belong to the stress-type PM fibers.