Do you really know about Fiber End-face Inspection?

Do you really know about Fiber End–face Inspection??

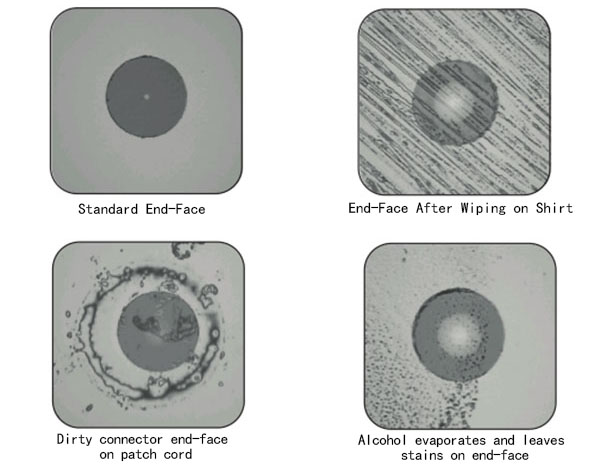

With the rapid development of the optical network era, fiber optic network operations are gradually standardized and standardized. As the end-face inspection in the fiber optic network operations play a vital role in the operation, so it is necessary to carry out strict control of this operation. Data show that in the fiber optic network operation in the detection of unqualified fiber, 95% of the end-face is not clean, and the end of the end-face is not clean because it is not connected to the equipment when the fiber optic end-face inspection operation.

Why is Fiber End–face Inspection so Important?

(1) During the production of patch cords, the polishing effect is detected to ensure that the polishing is in place

In the production of patch cords, we need to grind and polish the end-face of the optical fiber to ensure that the optical fiber end-face is smooth and clean, and the role of the end-face inspection is to ensure that the end-face of the patch cord is ground in place to avoid defective products from entering the market.

(2) In the fiber optic network operation, the lack of end-face inspection may affect the quality of optical network signal transmission

Fiber optic end-face inspection has become an essential part of fiber optic transmission network operations. If the end face inspection is not carried out before the network operation, it is easy to mistakenly use the connector with a damaged end-face, which may become the number one “killer” leading to fiber optic cabling failures, and fiber optic connectors between the tiny dust, oil, etc., will lead to the loss of optical communication signals, the formation of retro-reflections, damage to optical network equipment; at the same time, the presence of a large number of dirty fiber optic connectors will also contaminate other optical network equipment. At the same time, the presence of a large number of dirty fiber optic connectors will also contaminate other fiber optic connectors, resulting in increased optical signal attenuation loss, thus affecting the quality of optical network signal transmission.

What are the requirements for Fiber End–face Inspection?

Fiber end-face inspection also requires the use of appropriate end-face inspection equipment, if not using the appropriate end-face inspection equipment, data centers or network operations can not run quickly, but also greatly shorten the life of the optical module, but also on the entire optical network system has a serious impact. Therefore, before the operation of optical network must use the appropriate testing equipment for end-face inspection, and in accordance with the fiber optic end-face inspection standards to operate.

According to the IEC 61300-3-35 standard, which defines the standard values for fiber optic end-face inspection, there are about four standard values as follows to choose from, while both TIA and ISO standards refer to the IEC 61300-3-35 standard.

- IEC 61300-3-35 MM

- IEC 61300-3-35 RL ≥26 dB

- IEC 61300-3-35 MM

- IEC 61300-3-35 RL ≥26 dB

- IEC 61300-3-35 RL ≥45 dB

- IEC 61300-3-35 RL ≥55 dB (APC connector)

The fiber optic end-face inspection equipment of Shenzhen Neofibomainly contains the following kinds:

》FK3-421P Triple Adjustable Multifunctional Fiber Inspection Scope: suitable for batch production line of patch cord, three magnification options

》FK4-420P Auto-focusing Double-magnification End-face Inspection Scope: applicable to batch production line of patch cords, auto-focusing is available.

》FK4-420P All-in-one fiber optic end-face inspection Scope: economical, small size, suitable for production line operations

》FK4-410P Split fiber end-face inspection scope: economic end-face inspector, suitable for low-budget production line operation

》FK-H200 Handheld fiber end-face inspection scope: suitable for mobile and outdoor work.

》FV-7500 Portable fiber end-face inspection scope: suitable for mobile operation, outdoor operation, easy to operate

All of the above fiber optic end-face inspection equipment can carry out standard inspection operations on fiber optic end-face, no matter what kind of operating environment you need to be applied in we have the corresponding, suitable equipment.

Use a fiber optic end-face tester to check the fiber optic patch cord end-face for cleanliness and intactness of the end-face.

How to correctly clean the fiber optic end–face?

We found that the end-face is dirty in the end inspection process, we need to choose the appropriate fiber optic cleaning tools to clean the end face, such as cleaning the SC connector end face selection of 1.25mm cleaning pen is wrong, cleaning the LC female connector using 2.5mm fiber optic cleaning pen is also wrong …… although also use the fiber optic end face cleaners Although the fiber optic end-face cleaner is also used, the unsuitable cleaning tool not only fails to remove the end-face dirt, but also easily damages the fiber optic end-face. We need to choose the appropriate fiber diameter cleaner according to the connector type.

Fiber optic end-face inspection of small Tips have told you, you have learned? Quickly use it!