What is PM Fiber? How to manufacture PM fiber?

What’s Polarization Maintaining Fiber?

Before understanding what a PM fiber is, let’s look at what polarization properties are first.

Polarization is a property of transverse waves, which refers to the nature of transverse waves oscillating in a particular direction in a plane perpendicular to their direction of propagation. Light is an electromagnetic wave that propagates as a transverse wave, and its electric and magnetic fields are perpendicular to its propagation direction.

Usually, the direction of polarization of light is the direction of oscillation of its electric field. The polarization of light exists in three polarization states: fully polarized, partially polarized and completely unpolarized. Fully polarized light can be divided into three categories: when its oscillation trajectory is a straight line, i.e., only along the direction of the determined oscillation, known as linearly polarized light; when its oscillation trajectory is an ellipse, known as elliptically polarized light; when its oscillation trajectory is a circle, known as circularly polarized light.

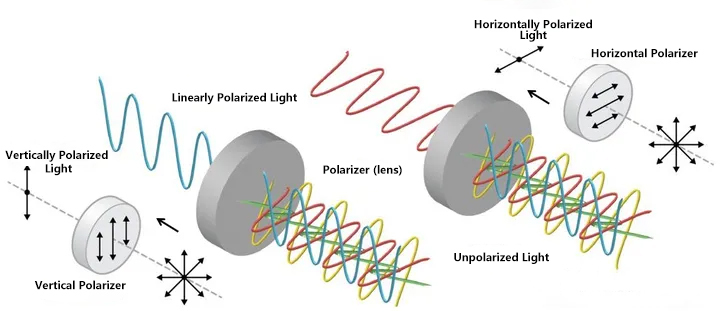

Natural light belongs to the completely unpolarized light, can be regarded as a collection of all directions on the line polarized light, and can be converted into polarized light, as shown in Figure 1. For example, when natural light is incident at a specific angle at the interface of two different media, the reflected light is linearly polarized light, the transmitted light is partially polarized, and this specific angle is the Brewster’s Angle, also known as the angle of bias, when the corresponding angle of the reflected light and the transmitted light is 90 °. The superposition of natural light and fully polarized light is partially polarized light.

【Picture 1】 Placing the polarizer at different angles produces corresponding line-polarized light

Polarizers, such as those commonly used in photography, take advantage of the polarizing properties of light. Polarizer lens body by a number of very fine crystal glass grating, when the natural light through the polarizer, these gratings will not be parallel to the polarized light it blocked, only allow its parallel polarized light through, this is the polarizer can eliminate or attenuate non-metallic surfaces reflections of the principle. Figure 2 shows the effect of the landscape with a filter.

【Picture 2】Polarizer filter, by rotating the polarizer at the right angle, the polarizer can attenuate reflections on the surface of the object and highlight the blue sky and white clouds, which is often used in still life and landscape photography

The optical signal transmitted by optical fiber has a similar situation. Single-mode fiber, although only the fundamental mode (LP01) can be stably transmitted, but from the point of view of the polarization state of the light, its fundamental mode can be decomposed into two modes with orthogonal polarization states LP01x and LP01y. for the ideal circularly symmetric single-mode optical fiber, its LP01x and LP01y modes can not be distinguished, it is a simple merger; but in fact, the long-distance optical fiber is difficult to achieve the perfect circularly symmetric in the production and When used, it will also be affected by external influences, so the LP01x and LP01y modes of general single-mode fibers are not simple and there is birefringence phenomenon.

Since the birefringence of single-mode fibers is inconsistent at each position along the axis, the transmission therein is usually a composite state of linearly polarized light LP01x and LP01y —- randomly varying elliptically polarized light. The polarization preserving fiber, as the name suggests, achieves the preservation of the polarization state of the incident light by artificially introducing birefringence so that the birefringence at each position in the fiber in the axial direction remains constant.

How to manufacture Polarization Maintaining fiber?

Conventional optical fibers are developed based on quartz glass materials, and after decades of development, the process procedures are basically finalized and also have a wide range of applications. The preparation process for conventional optical fibers is called a two-step process, i.e., preform preparation and fiber pulling. The process for bias-preserving optical fibers is a bit more complex, but it also needs to start with the preparation of preforms.

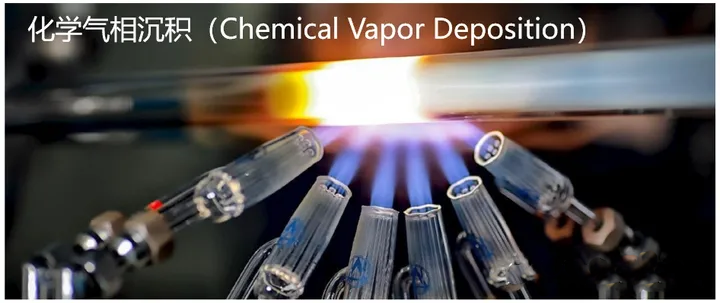

Step 1: Chemical vapor deposition (CVD)

Chemical Vapor Deposition (Chemical Vapor Deposition) process, quartz glass tube as a substrate (liner tube), the selected chemical gas carried by the oxygen together into the quartz glass liner tube, the use of traveling hydroxide flame moving along the tube on the liner tube to heat, cause a chemical reaction, and make the deposited material sintered on the inside of the tube (gas phase deposition), such as 【picture 3】. The number of deposited layers becomes more, the wall thickness increases, and the inner diameter decreases; ultimately, the hollow part of the glass tube is adjusted by pressure to “draw off” (thermal fusion shrinkage), and turns into a solid core of glass rods, completing the preparation of prefabricated rods.

【Picture 3】Typical chemical vapor deposition (MCVD) process

Step 2: Prefabricated rods for bias-protected optical fiber

In the case of conventional single-mode optical fiber, after the preform is manufactured using the chemical vapor deposition process, it is time to wait for the casing and fiber pulling, but bias-protected optical fiber is not so simple.

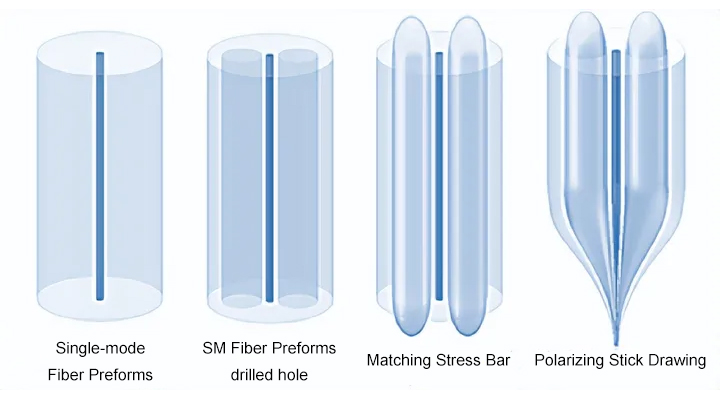

In the case of Panda bias-modified fiber 【Picture 4】, in addition to the preparation of the preforms, it is also necessary to prepare the mandrels, doped stress rods, and punch holes in the preforms. Only after the completion of the casing combination of all the preforms, the fiber will be pulled.

【Picture 4】: The main process flow of panda bias-containing optical fiber from prefabricated rod to wire drawing.

Step 3: Fiber Pulling

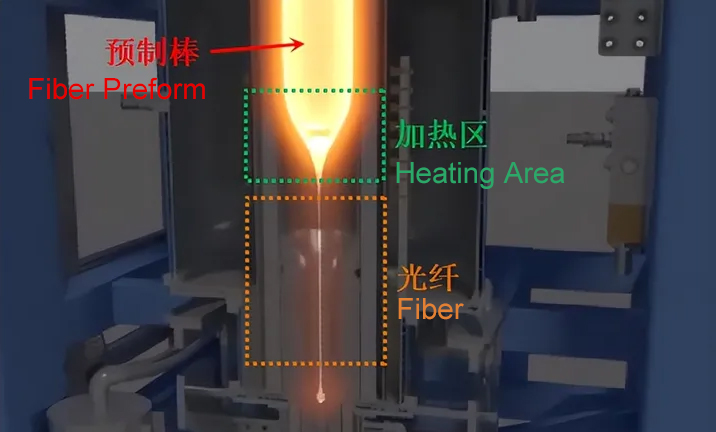

After the fiber optic pre-fabricated rods are prepared, they need to be cleaned, inspected and loaded into the drawing tower. Fiber optic towers are designed in a clean environment, usually over 10 m in height, and some telecommunication fiber towers can be dozens of meters high.

Bias-preserving fiber pulling and ordinary single-mode fiber is a little different, adding some sealing joint structure, the rest of the fiber pulling process is almost the same. Prefabricated rods gradually into the high-temperature furnace, the glass prefabricated rods soften, the lowest end of the drop, the formation of a cone, the lowest edge of the glass quickly “wire”, to be stabilized after the outer diameter, the formation of optical fibers, such as 【Picture 5】.

【Picture 5】: Fiber forming process in fiber pulling.

You can learn more about our products through our neofibo’s official website 《fibrekits.com》, or directly call us at +86-0755-86223060, we will be happy to serve you.